About Dust Extractor Vs Shop Vac

Wiki Article

Rumored Buzz on Dust Extractor Vs Shop Vac

Table of Contents3 Simple Techniques For Dust Extractor Vs Shop VacAll About Dust Extractor Vs Shop VacAbout Dust Extractor Vs Shop VacThe Greatest Guide To Dust Extractor Vs Shop VacNot known Factual Statements About Dust Extractor Vs Shop Vac 3 Simple Techniques For Dust Extractor Vs Shop Vac

The difficulties for shop dust collection systems focus on crystalline silica dust, carbon monoxide, and also heat, which are harmful mixes. These factors make conference air quality requirements hard and demanding. Consequently, when selecting a dirt control system for a shop, the first consideration is the capability of the device to endure extreme and harmful office problems.Besides the apparent conditions, the chosen devices needs to fulfill the regulations of OSHA, the EPA, and the NFPA. To meet those standards, dust collection systems utilize shakeout enclosures, collection hoods, melt, mold and mildew putting, cooling down hoods, and also exhaust heaps. Pleated bag as well as cartridge-style collection agencies have a very reliable purification system along with a portable dimension and lowered stress decline.

Dirt collection systems for this kind of procedure need to be particularly developed to fit the kind of layer being used. The objective of the system is to regulate as well as minimize overspray and also dust.

More About Dust Extractor Vs Shop Vac

It would seem most likely to increase air flow and motion, this kind of service might be ineffective and waste power. The design of the cubicle relies on the force of the air going into the cell or cubicle. For many systems, it is essential to have a small vacuum cleaner in the cubicle to avoid possible favorable stress.One more approach is simply putting the makeup air link on the top of the cubicle. No matter the layout, it is essential for the cleansing of the air to have cross ventilation. Just like a cleanroom, air movement in a thermal spray booth can be either horizontal or downward, though the down layout is best for dirt collection systems. dust extractor vs shop vac.

The pharmaceutical industry is a highly controlled market with considerable and also precise guidelines. Dirt from drugs is created primarily throughout the manufacturing and packaging of products - dust extractor vs shop vac. Each step of producing a drug, which includes granulating, drying, blending, pushing, covering, and grinding, creates large quantities of dirt that require to be removed.

The Greatest Guide To Dust Extractor Vs Shop Vac

HEPA filters are typically found in pharmaceutical dirt control systems given that they are one of the most effective and reliable. Similar to a factory system, they are set up as a secondary protection to attain no emissions. Reusing creates a large amount redirected here of dirt look these up as a natural outcome of lessening products to their resources.

Dirt comes from after materials are shredded, squashed, or have paint or lacquer removed. All reusing facilities are called for to comply with air top quality requirements. As they function to satisfy quality requirements and control toxins, they have acknowledged that dust control is a major issue, causing the large use dust collection systems to alleviate and contain the trouble.

Not known Factual Statements About Dust Extractor Vs Shop Vac

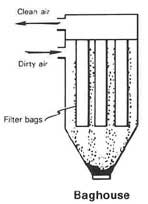

When makers choose a dust control system, they are encouraged by manufacturers concerning the kind of system that would best fit their demands given that acquiring as well as setting up a dust control system is a major investment. Particulate matter can be found in a variety of kinds, from silicon dirt to timber chips and also sawdust.Below is a brief list of the kinds of investigate this site bits that dirt collection systems can get rid of. Gypsum Gypsum needs a high-efficiency baghouse system with the ability of running at temperatures near 428 F (220 C). Felt Felt is used in apparel production and needs dirt collection systems at 3 phases of the procedure.

Sawdust This is the most typical material gotten rid of by dirt collection systems. Cartridge or baghouse techniques can be used, with baghouse being the most efficient.

The 10-Minute Rule for Dust Extractor Vs Shop Vac

Fabric filter bags in a cartridge system are the most effective approach for collecting dust. Dust collection systems are covered to contain the dust and also tidy the air.

With the intro of dust collection systems, workers are much safer and also more secured. Sugar Sugar dirt is the by-product of the production of sweet.

The Best Strategy To Use For Dust Extractor Vs Shop Vac

Rice Dust Rice dust has extremely fine and minute particles that accumulate throughout the manufacturing of rice-based products. dust extractor vs shop vac. A dust collection system is needed for the security as well as safety of employees.Report this wiki page